♦ FACILITY OVERVIEW:

1. Registered Company Name & Address?

2. Type of Facility?

3. Facility Description (size in square feet & configuration)

4. Incidents of flooding or other natural disasters in the last 100 years?

5. Total current availability of space (square feet)?

6. Additional amenities within facility?

7. Facility TIER rating?

♦ SECURITY:

1. Has your data center ever experienced any security incidents?

2. Perimeter security?

3. Security Procedures?

4. Access control?

5. Are your access controls multi-layered?

6. Are the windows alarmed?

7. What areas are accessible via windows?

8. Are the facility windows resistant to explosions?

9. Is roof access restricted, alarmed or monitored?

10. Do you use an offsite monitoring company to provide additional layers of security?

11. Will our company’s presence in the facility be advertised in any fashion?

♦ BMS (Building Management System):

1. Description of system?

2. Location of system?

3. Alarm monitoring?

4. Are all M&E plant alarms monitored?

♦ POWER:

1. Description of incoming electrical supply to site?

2. Are there multiple feeds to site?

3. Do multiple feeds provide for redundancy?

4. Details of standby generation?

5. How long can site be operated on standby generation?

6. Is there provision for connection of mobile generator?

7. What is redundancy of Uninteruptable Power Supplies?

8. Are A & B Uninteruptable Power Supply Systems available?

9. Are PDUs single or dual fed?

10. Is dual feed changeover by means of Static Switch (Load Transfer Switch)?

11. Design P.U.E at full load?

12. Power Provider?

13. Power Provider SLA?

14. Are there restrictions or limits on power and subsequent cooling capabilities to an individual cabinet or rack?

♦ AIR CONDITIONING:

1. Description of type of air conditioning system?

2. Does air conditioning have redundancy?

3. Does electrical distribution to cooling support the cooling redundancy?

4. Cooling design control range?

♦ FIRE DETECTION AND SUPPRESSION:

1. Fire Detection to technical space?

2. Fire Suppression to technical space?

3. Fire Detection to other areas (outside of colo)?

♦ RAISED FLOOR AREA:

1. What is the height of your raised floors?

2. Do you run cabling under the floors?

3. At what pressure is the raised-floor plenum maintained?

4. What is the designed or desired cubic feet per minute (CFM) of air flow in the delivery aisle per tile?

5. Is the entire data center space built on the ground floor?

6.Is your raised floor attached to the concrete slab?

7. Do cabinets or racks sit un-anchored on raised floors?

8. What is the load capacity of your raised floor in concentrated load and uniform load?

9. Is your raised floor grounded?

10. What are your minimum ceilings heights (measured from the top of the raised floor)?

11. Cabling methodology (power)?

12. Cabling methodology (network)?

13. Is there adequate space for critical components and systems infrastructure for growth and density?

14. What is the ratio of raised floor space to mechanical, electrical and critical systems space?

♦ PROCESSES AND SLAs:

1. What are your change management controls?

2. How is staff training conducted for processes and procedures?

3. What are your SLAs for electrical power availability?

4. What are your SLAs for environmental availability?

5. What are your SLAs for temperature and humidity?

♦ EQUIPMENT AND MAINTENANCE:

1. Has an electrical short-circuit coordination study been conducted?

2. Were the data center facility and critical-systems infrastructure commissioned by a third party or a commissioning agent?

3. Did the commissioning include an integrated systems test to validate the design capacities, redundancies and reliabilities of critical equipment in different modes of failure?

4. Are the electrical short-circuit coordination study, commissioning and integrated systems test reports available for review?

5. How often do you conduct your maintenance activities?

6. What types of maintenance activities are performed during the maintenance windows?

7. Does this maintenance work affect redundant circuits to computer racks or cabinets?

8. Are your generators tested at load? If so, how often is this performed and at what load percentage of the full-rated load?

9. What items are inspected and recorded during testing?

10. How do you control and manage installation and maintenance activities in the raised-floor areas and in the mechanical and electrical areas?

11. What is your policy for replacing critical equipment?

12. What is your process for evaluating and choosing critical equipment?

13. Who are the manufacturers of your critical infrastructure equipment?

14. Is any of your equipment reused or refurbished?

15. What is your cable management policy? How is it enforced?

16. How are critical infrastructure equipment and components labeled?

This system follows through to individual fire alarm points and emergency points which are allocated unique asset numbers. All major and critical equipment items have a unique asset number and are entered into our Computerised Maintenance Management System. We employ this system to maintain critical spares. plan maintenance, historical analysis, lifecycle management and many more critical activities.

17. How are circuit breaker panels and panel schedules managed and maintained?

♦ VALUE ADDED SERVICES:

1. Remote Hands and Eyes support:

2. Cloud Services:

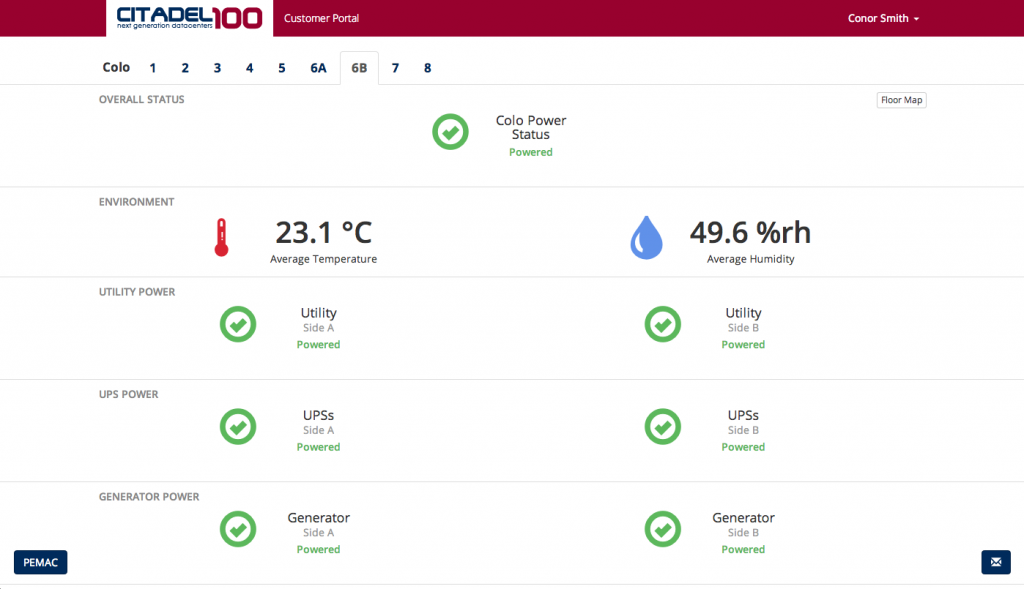

3. Customer Online Portal:

Citadel100 provides clients (at no additional cost) with C100, our customised online portal which provides you with a personalised view of your mission-critical environment utilising our bespoke BMS (Building Management System) – C100 provides real-time information on your data center temperature, humidity and additional environmental and energy reporting and has been programmed using responsive design to display on Desktop, Tablet and Smart Phones for ease of access.

It is linked to our data center PEMAC maintenance and monitoring system which allows you to place and track service orders and request security access when required.  Customer Portal screen

Customer Portal screen

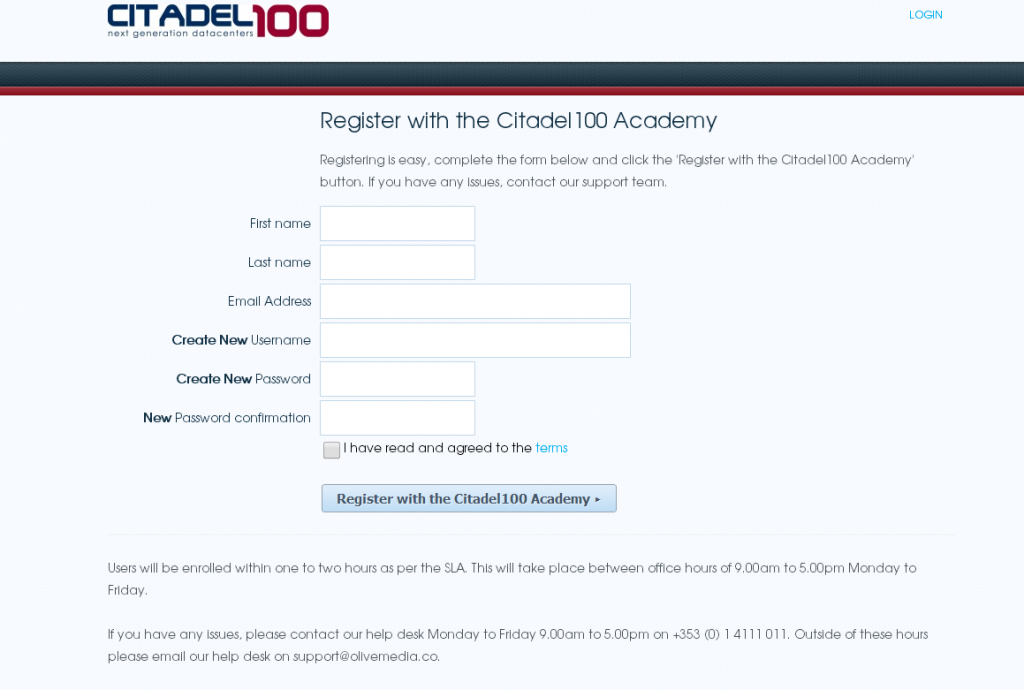

4. H&S Facility Induction Portal:

H&S Portal registration screen

♦ HOURS OF OPERATION:

1. Under what conditions can a customer gain access to the onsite colo and office space?

♦ CONNECTIVITY:

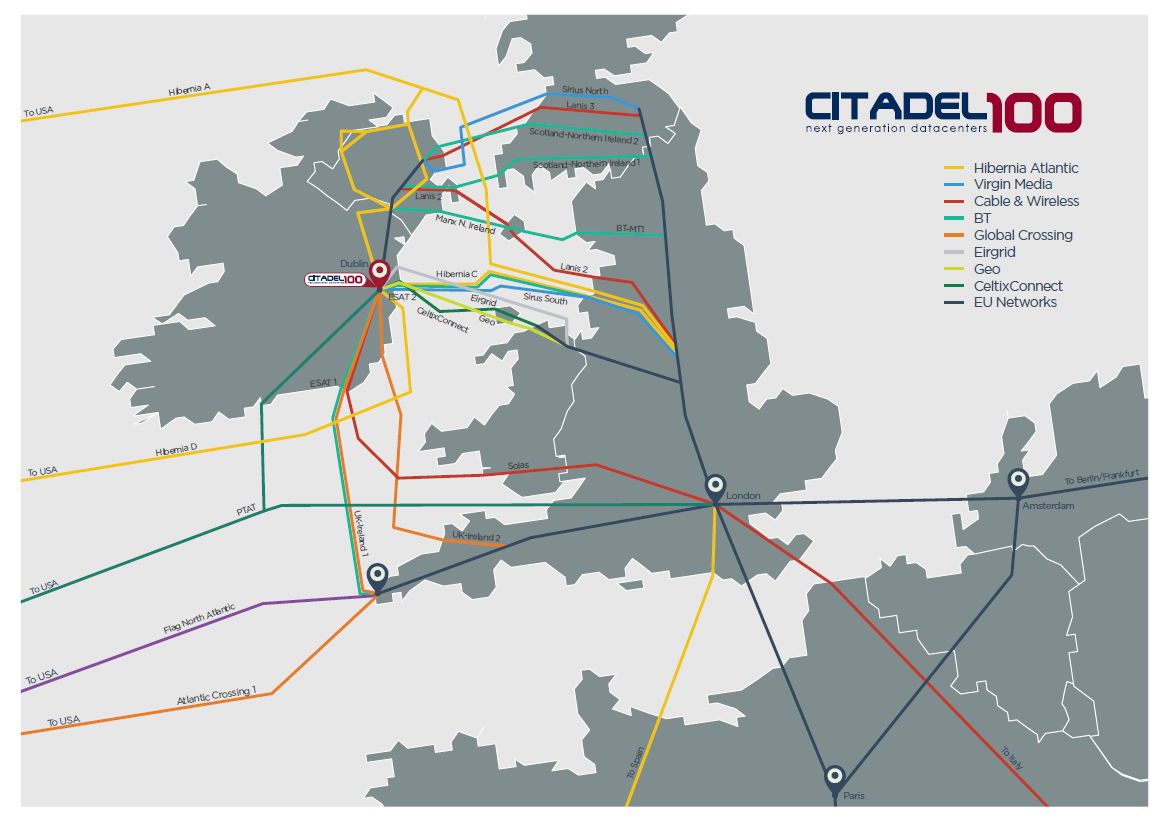

1. How close is the location to National & International fiber runs?

2. How do carriers get into building – confirm if there is diverse meet me rooms and fibre entry points?

3. Where does each carrier terminate (meet me rooms/meet me rack/individual cabinet/suite)?

4. Is circuit diversity available at the location from the carriers?

5. How do the carriers interconnect between the meet me room and equipment?

6. Carriers into building (Current)?

7. Is there a local internet NAP switch in the building?

8. Can the inside cabling be provided though diverse routes? (elevator shafts)

♦ OTHER

1. Is the data center located in an area that puts it at risk of earthquakes, hurricanes, floods, tornado’s or wildfires?

2. What are the company’s contingency procedures for other events or potential risks associated with the data center’s location?

3. Do you offer customers access to onsite office space?

4. Under what conditions can a customer gain access to the onsite office space?

5. Can we have equipment drop-shipped to the data center

♦ CERTIFICATION:

1. What Certifications does the data center have:

In 2007, Citadel100 introduced a quality management system (QMS) meeting the requirements of the international standard ISO 9001:2000. Since that year Citadel100’s Dublin Data Centre has been continually awarded recertification by independent auditors SGS.

Quality Management requires the constant improvement of company activities and raising the satisfaction level of customers. Maintaining and developing the system of Quality Management requires constant work on improving the management system, renewal of the production and technology base, getting feedback from customers and other company partners and taking their wishes into account. It is an essential requirement of the standard that staff be drawn into the process of improving the management system, including arranging internal audits.

Many of the strict processes surrounding environmental management and health and safety standards have long been in place in the Citadel100 Dublin data centre. The next logical step was for Citadel100 to adopt an integrated management system (IMS) in the areas of quality management, environmental management, and health and safety standards in compliance with ISO 9001, ISO 27001, ISO 14001 and OHSAS 18001 standards.

The processes in compliance with these standards will be fully implemented in the Dublin data centre and audited by our internal auditors. We will then be audited by our external independent auditors for all four standards as part of our IMS in Q1 2016.

An overview of the Certifications in place and in progress:

IN PLACE AND CERTIFIED:

ISO 9001:2008 Quality Management Systems Standard

ISO 9001 is the world’s leading quality management standard. An effective quality management system provides a clearly structured, systematic approach to maintaining and improving customer experience, and:

- minimizes the potential for incidents and mitigates any impacts

- ensures cost-effectiveness and clear lines of responsibility

- supports effective communication with hard facts and figures

- optimizes staff competences, commitment and motivation

Click to view current Certificate.

ISO 27001:2013 Information Security Standard

Our data centres have been awarded the ISO27001:2013 standard for information security management. It specifies the requirements for establishing, implementing, operating, monitoring, reviewing, maintaining and improving a documented Information Security Management System within the context of an organisation’s overall business risks.

Ultimately, the standard ensures best practice for security controls to protect information assets of the organisation and its clients.

Click to view current Certificate.

IN PROGRESS, PENDING CERTIFICATION (Q1 2017):

ISO 14001:2004 Environmental Management System Standard

ISO 14001:2004 provides a framework for ensuring that any and all interfaces between Citadel100 and the environment are closely controlled in a manner that avoids or minimises any negative environmental impact. The ISO 14001 standard:

- promotes procedures that have been made in an environmentally friendly and sustainable manner

- requires proactive management of any design and operational environmental risks

- supports Citadel100 and its customers in achieving lasting environmental and economic goals

OHSAS 18001: 2007 Occupational Health & Safety Management System Standard

This standard ensures that Citadel100s data centre is a safe and healthy environment to work in and visit. OHSAS 18001 requires that:

- any risks to staff, visitors and contractors have been assessed

- where necessary controls are put in place to reduce the risk of harm to a minimum

- all national/local legal and regulatory health and safety requirements are met.

♦ TAXATION: